|

"Rethinking The

Warehouse Workplace"

Engineered Certified Racking Repairs

All repairs are performed by D.C. Racking and Maintenance.

We as a company specialize

in the repair and maintenance of racking. We provide photos of before and

after pictures to the work performed by our qualified technicians and

"Engineered Approved Reports" of each completed job sent directly

to our customers. This report reviews photos provided by the technicians and

makes a determination as to whether the repairs are adequate. We as a company specialize

in the repair and maintenance of racking. We provide photos of before and

after pictures to the work performed by our qualified technicians and

"Engineered Approved Reports" of each completed job sent directly

to our customers. This report reviews photos provided by the technicians and

makes a determination as to whether the repairs are adequate.

Repairs to racks are modifications that must be treated rigorously with a

formal approval as required by Section 7 of Regulation 851. Subsection (2) of

Section 7 of Regulation 851 states when a Pre-start Health and Safety review

is triggered. A Pre-start Health and Safety Review is triggered when: (b)

because an existing apparatus, structure, protective element or process is to

be modified and one of the following steps must be taken to obtain compliance

with the applicable provision:

- New or modified

engineering controls are used.

- Other new or modified

measures are used.

- A combination of new,

existing or modified engineering controls and other new or modified

measures is used.

In most cases, the rack membets that have been repaired, which is a structural modification as specified in (b) above.

Our reports satisfies the requirement of Section 7 because it is written and

sealed by a Professional Engineer registered in the province of Ontario as

required by Subsection(11) of section 7 which states: (11) A pre-start health

and safety review required under item 1,2,3,4,5,6 or 7 of the table shall be

conducted by a professional engineer.

PROCEDURE

D.C.

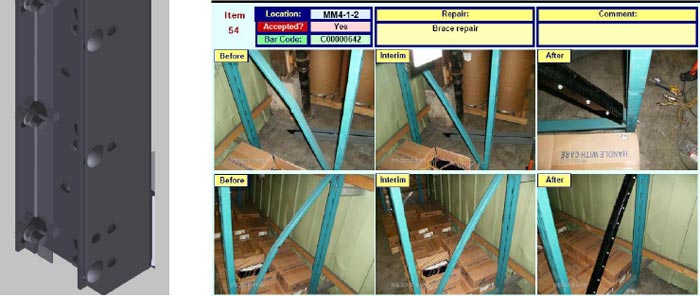

Racking and Maintenance technicians that do the repairs are required to

document several stages of the repair. The prime tool for documenting the

repair is a digital scanner. In general each repair is documented with up to

six photos. One or two photos are provided for each stage of the repair. The

three stages of repair are as follows:

- The first set of

photos document the condition prior to the repair process. This stage is

titled "before".

- A second set of photos

is taken after the severity of damage has been alleviated by manually

working the metal to bring it close to its original shape. This stage is

titled "interim".

- The third set of

photos is taken after the repair device has been installed. This photo

is titled "after".

- All repairs are then

marked with a serialized ID tag (stickers) that are referenced in

certification reports.

CERTIFIED

REPAIRS

Each

Repair is individually certified by a Professional Engineer

- Brace repair very

common

- Front post repair

common

A professional rack engineer reviews the photos documentation

of the repair part and the installation of the repair part, then issues the “Certification

Report” for each individually certified repair.

Advantages of Repairing vs. Replacing

The frame repair option is attractive in that the apparatus can be easily

installed and the resulting configuration is considerably more durable than

the original frame. In addition, the process of doing the repair is much less

disruptive. Also to consider when doing frame replacement is the cost of

scissor lift rentals, which can be very expensive, whereas repairs to the

bottom of the frame does not require any equipment rentals. Repairs can be

painted to match existing racking.

If moving rack it can

be repaired and certified If moving rack it can

be repaired and certified - Repairs are marked

with serialized ID tags (stickers) that are

referenced in certification report

- Typical repair for

damaged braces

- Where weld is damaged

brace extension required

- Missing braces can

easily be repaired rather than replacing the end frame

|

![]()

![]()